Rollover Car Wash Machine

Automatic car wash raises the standard for touch-less car wash equipment. With Revenue Enhancement and Total Cost of Ownership improvements being the main focus, this vehicle wash system delivers the industry’s best Return on Investment.

Product Description

The high-speed car wash system is one of our high-end types of the rollover car wash systems. After over 3 years of research and development, FWash has launched this car wash system with tire brushes to satisfy the higher requirements of some customers. The high-speed car wash machine can rinse different parts of the vehicle at one time, and hence save time and resources.

Function

1. High-pressure water rinse – foam wash – water wax spray

2. Voice prompt

Rollover car wash machine – To Attract Even More Customers!

With more than 10,000 LaserWashes shipped worldwide, PDQ Manufacturing Inc., takes great pride in being the leader in the in-bay automatic vehicle wash industry. We are dedicated to providing wash operators with the most innovative equipment that exemplifies our tradition of Performance, Dependability, and Quality.

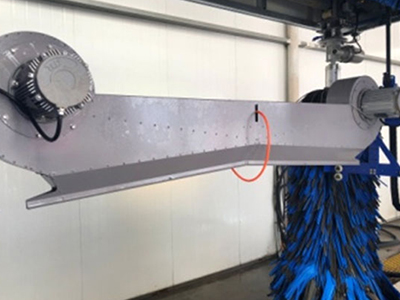

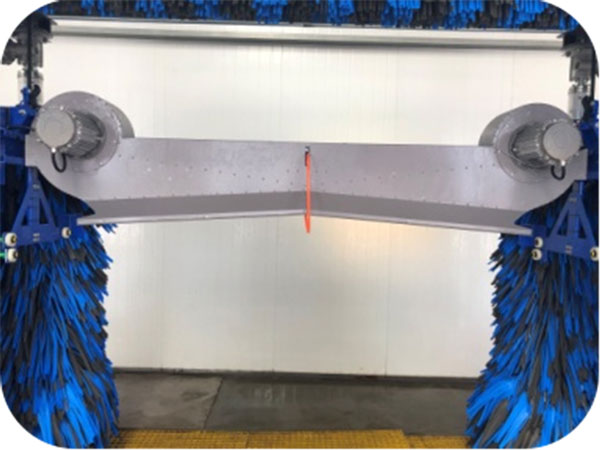

And NOW, the LaserWash raises the standard again with our latest advancement, the LaserGlow Arch. This illuminated wash arm not only helps wash customers get their vehicles loaded and unloaded faster, but also helps attract more customers to your wash – both of which mean HIGHER PROFITS for you!

- Fully-automatic PLC electronic control system improves the security.

- The galvanized door-shaped frame of the vehicle washing equipment features higher corrosion resistance and increases the service life.

- Powerful air dryers can follow the contours of vehicles to improve the drying effect.

- Foam and water wax proportioning system is easy to operate.

- Two-Click washing method simplifies operations.

- Built-in self-diagnose system can recognize and remove obstacles during car washing.

- 7 brushes (1 vertical lift overhead brush+2 small tire brushes+2 small vertical brushes+2 large vertical brushes)

- Aircraft grade anodized aluminum bridge and main rails – Now Standard

- Non-corrosive materials used – stainless and aluminum

- Stainless steel pump station design focused on improved functionality and low maintenance costs

- Ultimate cover package

- Welded manifolds replacing assemblies of fittings-reduces leak points

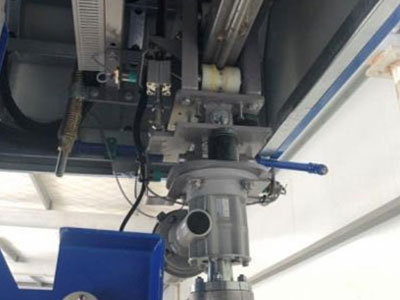

- It adopts PLC fully automatic computer control

- It adopts an upper-suspended double swing arm structure, which can achieve 360° car washing without blind spots and has a fast car washing speed.

- The equipment operates stably and reliably with high safety.

- Optimize the framework structure to occupy less space.

- It adopts the Japanese Welco liquid metering pump, which has a long service life.

- High-pressure water rinse – foam wash – water wax spraying

- Voice prompt function

- It can effectively remove various attachments, achieving a better cleaning effect.

- The 360° water jet high-pressure water system ensures no blind spots in cleaning and provides excellent cleaning results.

- Water wax makes the car body look as good as new and forms a protective film that adheres to the surface of the car paint.

Specifications:

| Overall dimension | 2.17m*3.6m*3.4m (L*W*H) |

| Rail length: 9m Wash bay width: 3.2m Installation height of drag chain:3.15m | |

| Installation size | 11m*4.3*3.6m Passage required on both sides for free access |

| Moving range | 11m*4.3m (L*W) |

| Voltage | AC380V 50Hz 20KVA |

| Water source requirement | Pipe diameter: DN25, flow≥80L/min |

| Air source requirement | 0.75~0.9Mpa (7.5~9.0kgf/ cm2) Flow≥0.1m³/min |

| Ground flatness | Error≤10mm |

| Cars washed | Sedan, jeep, van up to 10 seats |

| Car wash size | 5.4m*2.1m*2.1m (L*W*H) |

| Car wash speed | One rollover: 2’45” Two rollovers: 5’20” Three rollovers: 7’20” |

| Water consumption | One rollover 85L/car Two rollovers 110L/car Three rollovers 130L/car |

| Power consumption | 0.46-0.65kWh/car |

| Shampoo consumption | 15ml/car |

| Wax consumption | 20ml/car |

| Frame | Hot-dipped galvanized |

| Long brushes material | 4th-generation foam brushes |

| Wheel brush material | Nylon brushes |

| Tire brush motor | TLD |

| Side brush motor | TLD |

| Top brush motor | TLD |

| Driving motor | TLD |

| Air dryer motor | TLD |

| Water pump | Youli, Shanghai |

| Electric control system | MCU (Risense) |

| Frequency converter | China |

| Cylinder | AirTAC |

| Photoelectric sensor | Banner, USA |

| Proximity sensor | P+F , Germany |

| Contactor | Schneider, France |

| Reducer | TLD |

Rollover car wash machine is thus suitable for various sites

Rollover car wash machine adopts the advanced bearing technology that shortens the distance between the top brush and the top air outlet. The length of the car wash machine is as short as 1.5 meters, which increases the spatial efficiency. Rollover car wash machine is thus suitable for various sites.

Air dyer system

The air dryer system comprised of 4 air compressors and 4 outlets is effective to dry cars. Turned V-shaped side blow can increase the use ratio of air power as it reduces air offset.

Photoelectric sensor

The air dryer system is equipped with 3 pairs of photoelectric sensors that can identify the car body shape and keep air outlets 10cm away from the car. The design well protects customers’ cars.

Height limit device

The height limit device will stop the machine if cars touch it, which increases the safety of car washing process.

The function of the brush

Side brushes and wheel brushes of Fwash's rollover car wash machine are respectively made of cloth brushes and 4th generation of swallow-tailed sawtooth foam brushes. The combination of cloth and foam brushes performs well in terms of cleanness, quietness, durability, softness and safety, especially the foam brushes feature great capacity to retain water and reduce noise, which greatly improves user experience.

Wheel brushes

Pneumatic wheel brushes are made of nylons and they can wash deep into recesses and wheel rims.

Brushes tilting technology

Brushes smartly adapt to the car body shape in the tilted position to effectively clean car sides and the rears.

Intelligent control

Rollover car wash machine collects car exterior information with the use of raster scanning before a car enters the machine. Motion of top brushes will be processed and calculated by PLC and thus is stable and immune to external factors. The smart safety system comprised of photoelectric censors and touch censors guarantee the safety and stability of the whole car washing process.

Introducing the Touchless Car Washing Machine – the innovative, efficient and highly advanced car washing solution that is designed to provide a superior car washing experience, without the use of water. The Touchless Car Washing Machine is ideal for commercial use, catering to vehicle owners who are looking for a quick, efficient and environmentally friendly way to wash their cars.

One unique feature of the Touchless Car Washing Machine is its use of high-pressure streams of water and air to remove dirt and other harmful contaminants from a car’s surface. This means that the machine does not require any brushes or cleaning pads, which can scratch or damage the car’s paint. The touchless design of the machine also reduces the risk of any damage to the car’s exterior, making it a highly sought-after car washing solution.

The Touchless Car Washing Machine is specifically designed for commercial use and can effectively clean a variety of vehicles, including cars, vans, trucks and buses. The machine is configurable to suit the specific needs of your business, and it can be installed in a car wash bay, mobile vehicle or as a standalone unit.

This machine is highly efficient and effective in removing dirt and contaminants from every corner of the vehicle, without damaging the paint or other exterior components. Its advanced technology ensures that the washing process is fast, thorough, and effective. Unlike traditional car washing methods that can take a considerable amount of time and water, the Touchless Car Washing Machine is designed to be fast and efficient, reducing the washing time significantly.

The Touchless Car Washing Machine is also environmentally friendly, as it uses significantly less water than traditional car washing methods. By using high-pressure streams of water and air, the machine reduces water wastage and conserves this precious resource. This feature is crucial, especially in areas where water is scarce or where environmental concerns are a priority.

In addition to its technological advancements, the Touchless Car Washing Machine is also designed to be easy to maintain and operate. It is equipped with user-friendly controls and an intuitive interface to simplify the washing process. This makes it easy for operators to use and maintain, reducing the chances of costly repairs or downtime.

Customers that purchase the Touchless Car Washing Machine can enjoy reduced operating costs, a lower environmental impact, and improved customer satisfaction. This is a product that will provide a fast and effective car wash, without compromising on quality.

Overall, the Touchless Car Washing Machine is a must-have for any commercial car washing business. Its advanced technology, eco-friendly design, and ease of use make it an attractive option for businesses that want to provide a better car washing experience to their customers. By investing in this product, you can increase customer satisfaction, reduce operating costs and make a positive environmental impact.

Rollover Car Wash Machine Configurations

| Standard Devices | Optional Devices |

| Shampoo spray system | High-pressure water devices |

| Water wax spray system | water-repellent protective coating with high gloss finish |

| Contour-following drying system | Undercarriage wash system |

| Telescopic tire brushes | High-pressure prewashing water guns |

| Equipment data intellectualization | Self-diagnose system |

Can you use my existing 4000 wall mounts?

The LaserWash 360 Plus was designed to give you the ability to reuse a few items you may have already. You may be able to reuse the existing wall mounts as well as the undercarriage manifold. We tried to make the process as easy as possible for existing Laser4000 owners.

Is the machine available outside of the US?

YES! The machine is available worldwide and is CE certified.

Is the dryer shut off for open bed pickups a set function or can it be disabled?

The dryer shutoff is a configurable function; it can be disabled or enabled per machine. This option is configured during the wash setup. The demo did not show it, but there is also the ability to turn off only the center dryer producers so that the side producers continue to dry the sides of the truck box (for open bed pickups).

Does this machine have the nodes like the M5?

The LaserWash 360 Plus does use nodes. The machine control system consists of the pump node, bay node and bridge node.The LaserWash 360 Plus does use nodes. The machine control system consists of the pump node, bay node and bridge node.

What size bay will the LaserWash 360 Plus fit into?

The recommended bay should be 15′ wide (for wall mount) x 11′ high x 28′-10″ long. These are the recommended bay dimensions; please contact your local distributor for minimum dimensions.

The LaserWash 360 Plus can handle an impact at the rear of a vehicle, but what about the sides (mirrors) and front?

The LaserWash 360 Plus handles impacts in a similar fashion around the entire vehicle, not only the rear. If an impact occurs with an extended mirror, or with something on the front of the vehicle, it will reverse course, back away and try to clear the obstacle. This will happen as many times as it takes to clear the obstacle until an extent is reached (machine can’t move back any further). This is all part of our Smart 360 design efforts.

Is the pump the same as the existing Laser4000's pump and does it use 1 or 2 pumps for solutions?

The main pump used in the LaserWash 360 Plus pump station is the same model (General or CAT) as the LaserWash 4000. The solution application uses one separate dedicated solution pump.

Does the dryer stay on over an open bed truck?

The demo did not show it, but for the open bed there is also the ability to turn off only the center dryer producers so that the side producers continue to dry the sides of the open truck box.

Does the spray arch automatically reset like it does on the G5?

The LaserWash 360 Plus does reset itself similar to the G5 platform. We have many additional arch improvements that we will address in the video.

How is the truck bed measured or is it a selected wash package, and how does it handle pickups with bed covers?

The sensor that is used to detect the rear of the vehicle is also used to detect if the vehicle has an open bed. The sensor watches for height difference between the top of the cab and the bed of the pickup to determine that there is an open bed. This is not a special wash package. The feature can be enabled or disabled per machine in the wash setup screen. If there is a cover on the bed of the pickup and the difference in height between the top of the cab and the top of the cover is not too great, it will treat the cover as a normal part of the vehicle and not as an open bed.